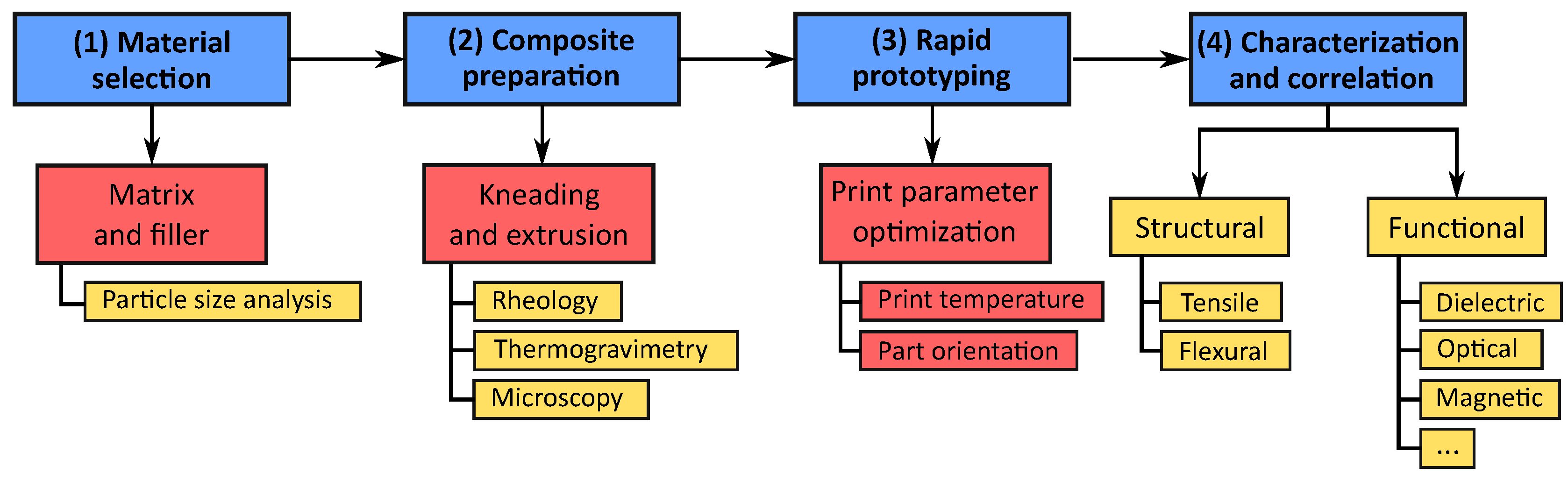

Unique polymer ceramic composites for microwave antenna applications were prepared via melt extrusion using high density polyethylene hdpe as the matrix and low density polyethylene ldpe coated bao nd 2 o 3 tio 2 bnt ceramic powders as the filler.

Polymer ceramic composites for microwave applications.

By incorporating ldpe into the composites via a coating route high ceramic powder volume content up to 50 vol could be achieved.

Polymer ceramic composites have also been investigat ed 14 16 recently chen et al 17 reported the microwave dielectric properties of ptfe sio 2 composite and due to its low relative permittivity e r54 which cannot be used for the miniaturization of microwave devices.

Fabrication and performance assessment january 2007 ieee transactions on microwave theory and techniques 54 12 4202 4208.

All the works mostly.

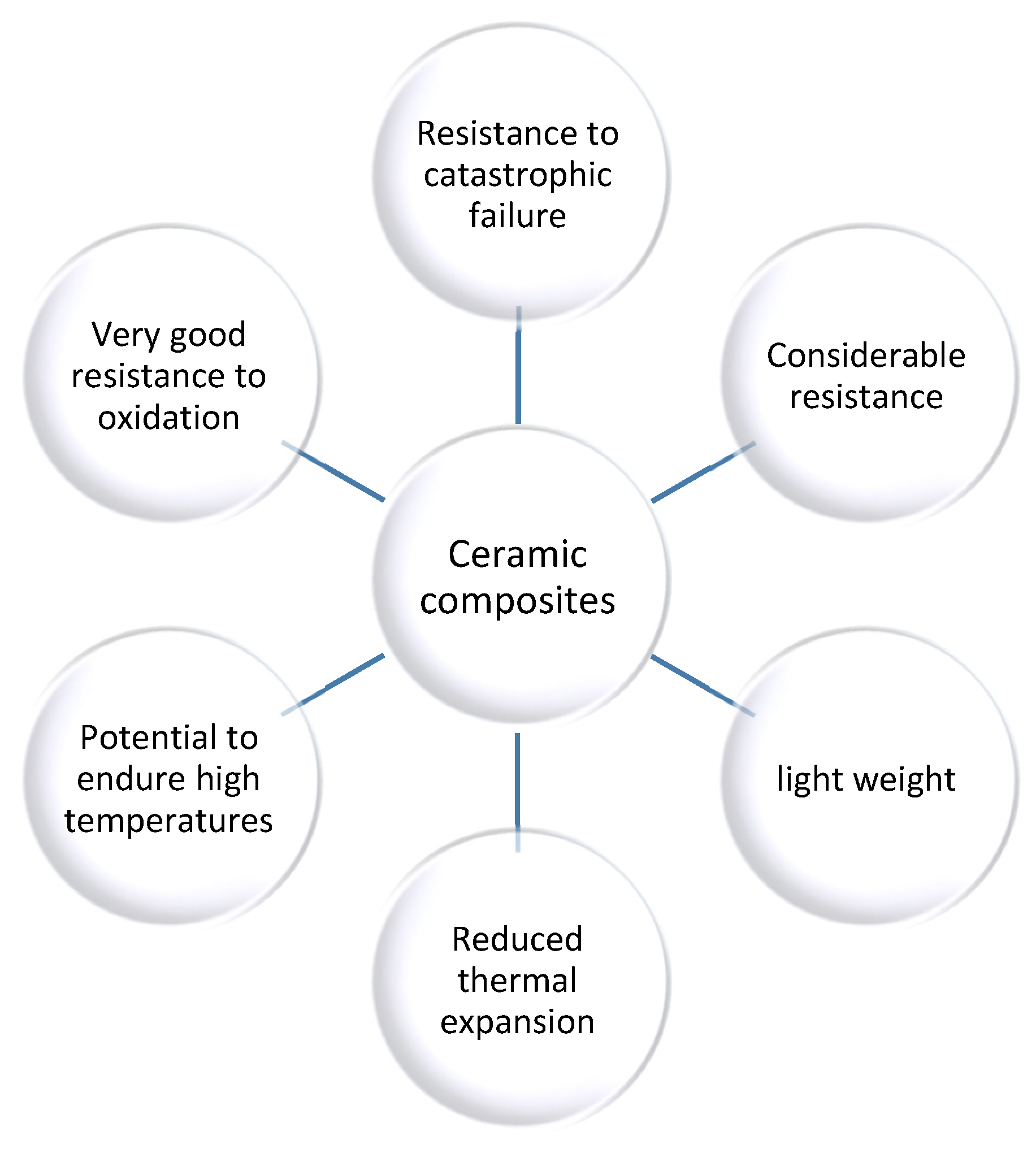

They can also be amorphous or have inhomogeneous chemical composition which develops upon pyrolysis of organic precursors the high process temperatures required for making cmcs preclude the use of organic metallic or glass fibers only fibers stable at temperatures above 1 000 c 1 800 f can be used.

Polymer ceramic composites especially type 0 3 are a poten tial group of materials suitable for producing functional packages that combine the electrical properties of ceramics and the mechan.

Ceramic fibers in cmcs can have a polycrystalline structure as in conventional ceramics.

The produced materials are fabricated by combining ceramic powders with polymers to generate a high contrast.

Polymer ceramic composites for microwave applications.

Interestingly the incorporation of polystyrene ps by the coating route could significantly improve the thermal behaviors of the composites hdpe ps bnt besides the temperature.

Polymer ceramic composites were prepared by twin screw melt extrusion with high density polyethylene hdpe as the matrix and polystyrene coated bao nd2o3 tio2 bnt ceramics as the filling material.

Ptfe based composites involving ceramics with high.

In the previous works about high dielectric constant ptfe composites the ba mg 1 3 ta 2 3 o 3 ba 4 2 nd 9 2 ti 18 o 54 teo 2 li 2 mg 3 tio 6 na 0 6 li 0 4 0 5 nd 0 5 tio 3 li 2 tio 3 ceramic powders had been added into the ptfe matrix to fabricate composites for microwave substrate applications 19 20.

Microwave packaging technology demands substrate materials with high frequency compatibility minimal dielectric losses low coefficient of thermal expansion and high thermal conductivity.

Polymer ceramic composites for microwave applications.

We present a novel technique to fabricate conformal and pliable substrates for microwave applications including systems on package.