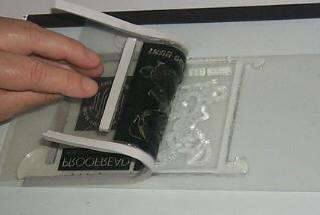

This is chemical process for easy where with the use of photographic material and special exposing light you can convert liquid polymer to solid rubber sheet with your.

Polymer rubber stamp making process.

About us prabhat rubber stamp mfg.

Was established in 2005 in mumbai india the most popular indian brand in india and out side the india too we are a reputed company in the rubber stamps industry since 13 years.

Honbay 6 sheets different theme friendly phrases pretty patterns silicone clear stamps for card making.

Polymer nylon rubber stamp flash stamp making machine very low budget create own business.

Additionally you can initiate the rubber stamp making as a home based business with comparatively small startup capital.

4 3 out of 5 stars 136.

Introduction we start your professional business very low price 365 days running business any support provide to you free timing.

Because so much of the rubber stamp making process is done by hand quality control is built into the process.

Rubber stamping also called stamping is a craft in which some type of ink made of dye or pigment is applied to an image or pattern that has been carved molded laser engraved or vulcanized onto a sheet of rubber the rubber is often mounted onto a more stable object such as a wood brick or an acrylic block.

Lisa pavelka polymer clay art supplies style 184 rubber mold texture stamp cloodlette.

The process of making a polymer stamp is a fairly straightforward once you know the basics.

There are two pieces of equipment that you will need to make to expose your rubber stamps although both are very simple to make.

The manufacturing process is simple and various different types of rubber or polymer stamps are becoming popular nowadays.

Simply put photopolymer is a liquid polymer that is reactive to uv light and will harden when exposed.

The process of making a polymer stamp is a fairly easy once you learn the basics.

Rubber stamp making business revenue wise has very good income potential.

Our traditional business model is based on the manufacturing of rubber stamp making machines and we deal with all kinds of rubber stamp products such as rubber stamp.

Knowing this a negative can be made that allows the uv light to show through only where the stamp image is to be.

Increasingly the vulcanized rubber image with an adhesive foam backing is attached.

Quality is also ensured by using only the finest materials.