Usually they are metal oxides that is compounds of metallic elements and oxygen but many ceramics.

Properties of ceramics and their uses.

These material properties are utilized to produce number of commercial and domestic products such as pottery bricks advanced functional items etc.

Ceramic engineers use this technique to tune the mechanical properties to their desired application.

Some ceramics cubic boron nitride are good conductors of electricity.

But fine ceramics and porcelain are insulators that do not conduct electricity.

Properties and uses of ceramics ceramic materials are abundant on earth.

Their varied chemical composition is very important because it includes a significant part of the 118 items of the periodic table.

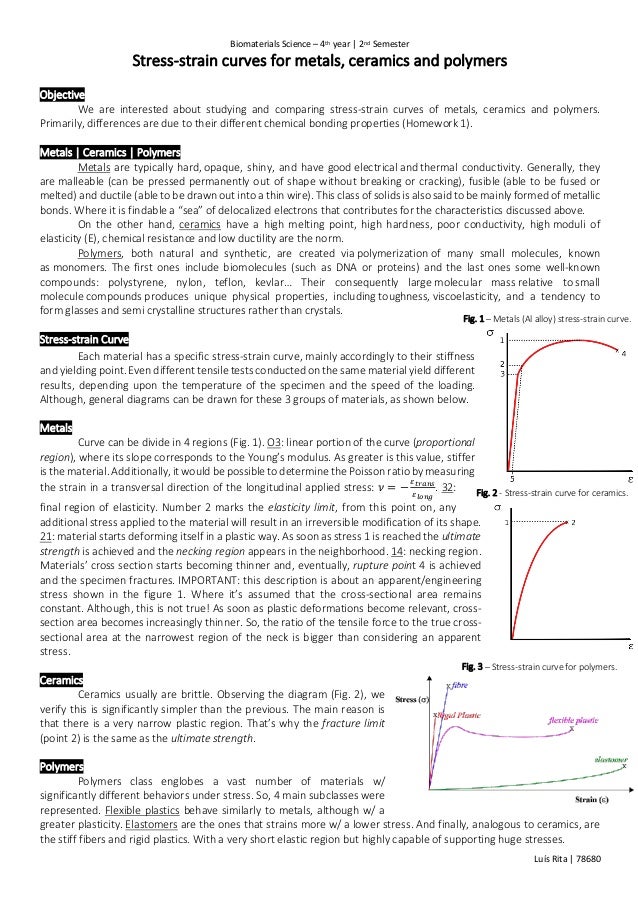

Ceramic products are hard porous and brittle.

Ceramic composition and properties atomic and molecular nature of ceramic materials and their resulting characteristics and performance in industrial applications.

In chemistry ceramics refers to any non metal non organic solid.

As a result they are used to make pottery bricks.

Ceramic cups and pottery are not the only uses of ceramics the word ceramics has a very broad definition.

Table of contents.

Advanced ceramics and traditional ceramics are the main categories of ceramic materials.

Learn about the characteristics of various types of ceramics along with their uses.

There s quite a big difference between age old general purpose.

Some ceramic foams are less brittle than their solid counterpart because air pockets may prevent cracks in the material from spreading.

Ceramic foams are generally less strong than a solid ceramic but may be very strong relative to their weight.

People first started making ceramics thousands of years ago pottery glass and brick are among the oldest human invented materials and we re still designing brand new ceramic materials today things like catalytic converters for today s cars and high temperature superconductors for tomorrow s computers.

If ceramic is subjected to substantial mechanical loading it can undergo a process called ice templating which allows some control of the microstructure of the ceramic product and therefore some control of the mechanical properties.

Ceramics are generally bad conductors.

They may be as much as 96 gas by volume.