Traditional ceramics ceramic materials that are derived from common naturally occurring raw materials such as clay minerals and quartz sand through industrial processes that have been practiced in some form for centuries these materials are made into such familiar products as china tableware clay brick and tile industrial abrasives and refractory linings and portland cement.

Properties of traditional ceramics.

Traditional ceramics are comprised of three basic components clay silica quartz and feldspar.

In fact properties of ceramics and glass can be tailored to specific applications by modifying composition including creating composite materials with metals and polymers and by changing processing parameters.

Bricks pottery glass porcelain tiles cement and concrete are our classic time tested ceramics.

Clay is one of the most common ceramic raw materials.

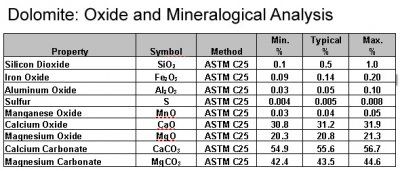

These are typical properties.

Traditional ceramics is used as a more general term representing all the more familiar ceramic products in domestic industrial and construction applications mclaren 1986.

Although they all have different uses we can still think of them as general purpose materials.

Ceramics play an important role in our day to day life.

Development of ceramics helps to decrease the demand in industries.

The table below provides a summary of the main properties of ceramics and glass.

Traditional ceramics are bio inert with inherent properties of high hardness and high compressive strengths coupled with low coefficients of friction which make them suitable for hard tissue and joint repairs 93.

This definition includes refractory products as well as spark plugs and thus covers certain of the oxide ceramics.

It is used widely because it is found in great quantities naturally and it is easily formed.

Ceramics usually withstand high temperature but it has poor mechanical properties.

Compare to other materials ceramics have some unique properties.